Adhesive Peel Tester specialty store|adhesive peel strength : exporting Thwing-Albert Instrument Company sells testing equipment for adhesion strength and other adhesive physical properties, such as seal and peel analysis. Browse our selection of . web25 de jun. de 2020 · A ex-atriz pornô Mia Khalifa fez um apelo para suas seguidoras nas redes sociais: "Meninas, não façam isso. Não vale a .

{plog:ftitle_list}

Resultado da Playstation 3 em até 24x* no site ou aplicativo. Compre Playstation 3 com o Carnê Casas Bahia e com frete grátis*

ASTM D3330 Test Methods. ASTM D3330 includes six distinct test methods (A-F) to evaluate different types of peel adhesion. Here’s an overview: Method A – Measures 180° peel .ASTM D1876 is a test method that measures the peel separation strength of two flexible materials that have been bonded together. This is commonly referred to as the “T-Peel” test because the sample looks like the letter “T” when loaded .

polarimeter sugar industry

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing .Thwing-Albert Instrument Company sells testing equipment for adhesion strength and other adhesive physical properties, such as seal and peel analysis. Browse our selection of .Qualtech Products Industry Peel Tester is an Automatic Peel Tester for flexible bonded to rigid test specimen to measure the Adhesive Strength of a wide range of samples at the touch of a button including adhesives.

ASTM D3330 describes methods for determining the peel adhesion of pressure-sensitive tape. It encompasses various methods for evaluating the adhesive properties of both single-coated and double-coated tape as well as adhesive .

polarimeter sugar rotation

ChemInstruments offers a wide range of adhesive and release testers including the AR-1000, Peel Adhesive Testing Machines, Release Machines and Unwind Machines for use in adhesive testing laboratories.ASTM D3330 is a major peel testing standard that outlines the requirements for determining the peel adhesion properties of pressure-sensitive tapes such as surgical, electrical, packing, and duct tape. The standard includes 6 different . A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging components. It simulates real-world scenarios by applying a . A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion .

polarimeter supplier

Peel Adhesion Tester: An Overview of the Machine. A peel adhesion tester is a specialized instrument designed to measure the adhesive strength of materials, including tapes, labels, films, and other packaging .

A wide range of adhesive properties can be measured by applying tensile or compression forces in a controlled manner. Figure 1. Single- and Twin-Column Materials Testing Machines Figure 2. Test Jig Showing 90. Peel Test on a Pressure-Sensitive Barcode Label Materials testing machines provide a powerful way of evaluating adhesive performance. A .The bonded test pieces can also be exposed to potentially detrimental storage conditions such as extremes of heat, cold, artificial sunlight or immersion in product chemicals before testing for peel adhesion. Alternatively, the peel test can be made at high or low temperatures to simulate harsh product environments.Test Procedure: Clamp each ends of the t-peel specimen in separate test grips of the universal tester / tension testing machine. Separate the specimen at a rate of 127 mm (5.0 in) /min for (5-in.) length of the bond line. Specimen size: Specimens are cut from a T-peel panel to 25.4 mm (1.0 in) long x 300 mm (12 in) wide. Ten specimens are .ASTM D903 | Adhesives | Peel Testing. Prepare at least 10 specimens according to the guidelines in the specification. A specimen consists of a flexible adhesive capable of folding back and peeling at a 180 degree angle as well as a substrate material to bond the adhesive to. The substrate object may be wood, textile, metal, or rubber.

Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel adhesion, in this context, refers to the force needed to remove a pressure-sensitive coated material from a standard test plate under specified conditions, at .

A number of standard test methods are used in the U.S. to measure the peel adhesion or bond strength of pressure-sensitive labels. These include ASTM D 903, ASTM D 3330, ASTM D 6252 and the TLMI 180° Peel Adhesion-Face Stock test method. In addition, as the need to compare test results from other parts of the world increases, it is important to be .

180° Peel Test: The most common test, peeling the substrate away from the adhesive at a 180-degree angle. Ideal for evaluating general bond strength. Ideal for evaluating general bond strength. 90° Peel Test: Similar to 180°, but with a 90-degree peel angle. Many adhesives exhibit different properties when subjected to variations in temperature. Some of these adhesives are thermoplastic. They soften when heated and become more brittle when cooled. [In the case of pressure-sensitive adhesives (PSAs), the nature of the bond is nearly always thermoplastic.] If for the sake of this discussion we limit our testing to .

peel testing machine

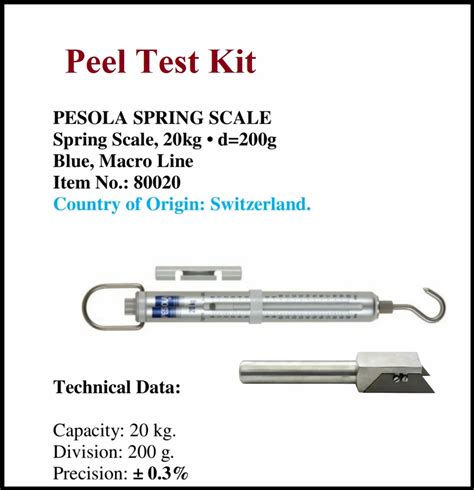

peel testing kit

The Peel Adhesion Tester - UniTest is highly configurable testing equipment. The tester can conduct 90 degree, 180 degree and loop tack peel adhesion tests. . tags: adhesive test, adhesive test equipment, adhesive test machines, adhesive tester, adhesive testing, positest pull-off adhesion tester, coating adhesion tester, portable pull-off .ASTM D903 Peel testing gives information about the bond strength created between an adhesive and a substrate. Standards ASTM D903, ASTM D1876, ASTM D3330, ASTM D6862. . ASTM D1876 – Peel Resistance of Adhesives (T-Peel Test) ASTM D3330 – Peel Adhesion of Pressure-Sensitive Tape;

Ecological Testing: This classification incorporates tests that survey a material’s presentation under reproduced natural circumstances, including UV obstruction testing and enduring testing. Conclusion. Peel strength testing plays a pivotal tool in assessing adhesive properties, playing a crucial role across diverse industries from medical .

peel testing equipment

Adhesive peel tester Product Introduction: Adhesive peel tester is an multifunctional tester, a ccurate and effective peel tester testing with 90 ° and 180 ° tape peeling, peel tester be with s ervo motor drive, precision ball screw drive, the computer set the test speed directly for adhesive force the physical property of strength resistance.Work with us to find the right equipment for your ASTM standard ASTM D3330 | Adhesives | Peel Testing Pressure sensitive tape is used in a variety of applications including duct tape, electrical tape, masking tape, packaging, double-sided tape, bandages, medical devices, and other uses. ASTM D3330 includes six different methods for testing theISO 8510-1 Adhesives Peel test for a flexible-bonded-to-rigid test specimen 90 degree peel; ISO 8510-2 Adhesives Peel test for a flexible-bonded-to-rigid test specimen 180 degree peel; . As a provider of adhesion promoters and other .

Peel adhesion testing is measuring the force required to remove a tape specimen from a test panel at a controlled angle (usually 180°or 90°), at standard rate, and with a defined dwell time. The tape is applied using a .

Do Many Testing Procedures Exist? The phase angles must be known in order to assess and perform a peel test, and the adhesive strength varies with peeling angle. Methods of testing range from the following. Single-coated, peel at a 180-degree angle. (Single-coated film) Peeled at a right angle to the surface. Evaluation of bond flexibility by T .Test angle is permanently set for 180° testing; 10 pound load cell is included with the machine; Capable of pulling up to 10 lbs (4.5 kg) Test samples as short as 1/2” to as long as 6” (12-150 mm) Designed to accept standard 2” x 6” peel panels (50 mm x 150 mm) Increments of 1.25 - 11.25 cm / .5-4.5 in.

Peel Strength The method of separation can also affect the measured peel strength of an adhesive. The basis of the peel test is shown schematically in Figure 2. For example, a thin substrate such as a metal foil is bonded to a thick, rigid . Test laminates consisted of 25 g/m 2 dry adhesive between Mylar (PET) film and siliconized release liner. 180° peel adhesion was determined in accordance with test method PSTC-1 with a five minute dwell time. All tests were performed at 23°C, 50% relative humidity.There are many test methods used to determine the strength of an adhesive including peel, shear, cleavage, and tension tests. Peel tests are common for tapes, labels, coatings, and other bonded materials. There are three main types of peel tests including 90 degree peel test, 180 degree peel test, and a T-Peel test. The Loop

ISO 11343 is a standardized Wedge Peel Impact test method used to measure the resistance of high-strength structural adhesives to cleavage fracture at various speeds and user-defined temperatures. The impact test consists of a wedge with a defined shape and mass, being driven at a defined velocity into the adhesive bond securing two metallic .

The ADMET eXpert 7601 adhesive and peel testing system has been designed to allow users to perform a wide variety of adhesive tests on a single easy to use and compact instrument. You can confidently report results knowing that the system has been engineered to meet all accuracy requirements specified in major standards organizations including . At measurements of high peel rates, such as those commonly employed using the 180°-peel test, the viscoelastic effects dominate, while at low peel rates, the viscous portion is minimized, which reveals the interfacial strength. The accuracy of the ADT’s displacement transducers enables the measurement of crack speed to be as low as 10-9 m/s.This test is optimized for tapes with flexible backings, or tapes that are adhered to a similar flexible substrate. Unlike the 180 degree peel test and 90 degree peel test, the T-peel or trouser method is the easiest test to set up and conduct. These types of tests are often done on transfer tapes or at converting companies that may use tape to .

ASTM D903-98 is a common tensile test used to evaluate the Peel-Stripping Strength of Adhesive Bonds. Back; Home; Products. Materials Testing. Universal Testing Systems. Automated Testing Systems. . To perform a test to ASTM D903, the adhesive materials must be cut into specimens 1" x 12" long. The specimens are then peeled away from either a .Adhesives — Peel test for a flexible-bonded-to-rigid test specimen assembly — Part 2: 180° peel Adhésifs — Essai de pelage pour un assemblage collé flexible-sur-rigide — Partie 2: Pelage à 180° This is a preview of "ISO 8510-2:2006". Click here to purchase the full version from the ANSI store. ISO 8510-2:2006(E)

polarimeter suppliers

polarimeter suppliers in india

web.club - Free Mods for iOS & Android - AppTap. Match Masters Mod. Unlimited Coins! AppTap. N.O.V.A. Legacy Mod. Unlimited Money & Trilithium! AppTap. Forge of Empires .

Adhesive Peel Tester specialty store|adhesive peel strength